Hazards Associated with Transporting Cryogens:

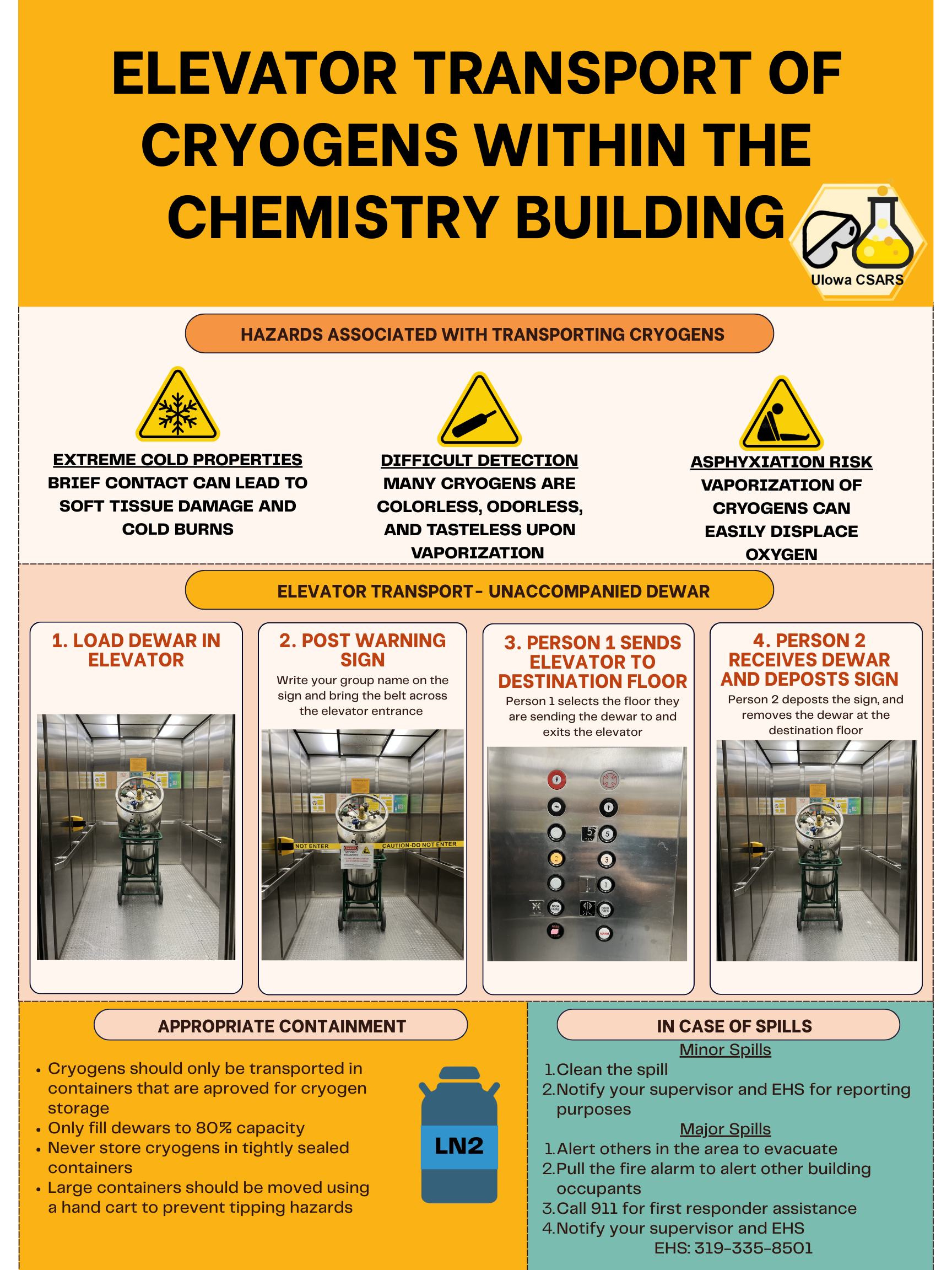

Non-flammable cryogens, such as liquid nitrogen (LN2), are hazardous materials due to their extreme cold properties (boiling point below -150 ℃), asphyxiation risk, and potential for pressure buildup and explosions. Brief contact with cryogenic materials can lead to soft tissue damage or frostbite, and prolonged contact can lead to the development of blood clots. LN2 expands 695 times in volume when it vaporizes and can easily displace oxygen in confined spaces if enough LN2 is vaporized. Gaseous nitrogen is colorless, odorless, and tasteless, making leaks difficult to detect without appropriate monitoring systems. A reduction in oxygen content of the air to 12-19% can lead to symptoms of fatigue, loss of coordination, and errors in judgement. Reduction in oxygen content to 12% or less can lead to rapid loss of unconsciousness and asphyxiation. These qualities are particularly important in considering the hazards of transporting LN2 in elevators due to the small, confined area, lack of good air flow within elevators, and potential to become trapped in the elevator with the cryogen dewar if the elevator malfunctions.

Best Practices for Transporting Cryogens

Personal Protective Equipment (PPE). Appropriate PPE should always be worn when handling or dispensing cryogenic materials. Cryogenic liquids are prone to splashing due to their large volume expansion ratio. Chemical splash goggles and face shield should be worn. Loose-fitting thermal insulated or leather gloves, long-sleeved shirts, pants without cuffs, and closed-toed shoes that will not soak in the liquid in case of a spill (leather/non-woven material instead of mesh) should be worn when handling cryogenic materials. Nitrile gloves are not sufficient PPE for handling cryogenic materials as they can trap cryogenic materials between the glove and your hand.

Safe Transport to Labs. Cryogenic materials should only be transported in containers that are approved for cryogen storage. Materials such as carbon steel, plastic, and rubber become brittle at LN2 temperatures (-195 ℃). They should also only be stored in containers with loose-fitting lids as tightly sealed containers will build up pressures to dangerous levels. Dewars should only be filled to 80% capacity to prevent excessive pressure buildup. Large cryogenic liquid containers should be moved using a hand truck or cart that can keep them upright to prevent spills and tipping hazards.

Additional safety precautions should be taken when transporting cryogenic materials on elevators. Cryogen dewars should be transported in freight elevators as opposed to passenger elevators when possible. Quantities of LN2 that cannot reduce the concentration of O2 in the air to lower than 19.5% are acceptable to travel in an elevator accompanied by people. For the elevators in the chemistry building, this is 0.5 L for the Freight elevator, and 0.4 L for the East and West passenger elevators (see Appendix 1 for volume calculations). When transporting volumes of LN2 greater than these amounts, cryogens should be transported in elevators without people (i.e. unaccompanied).

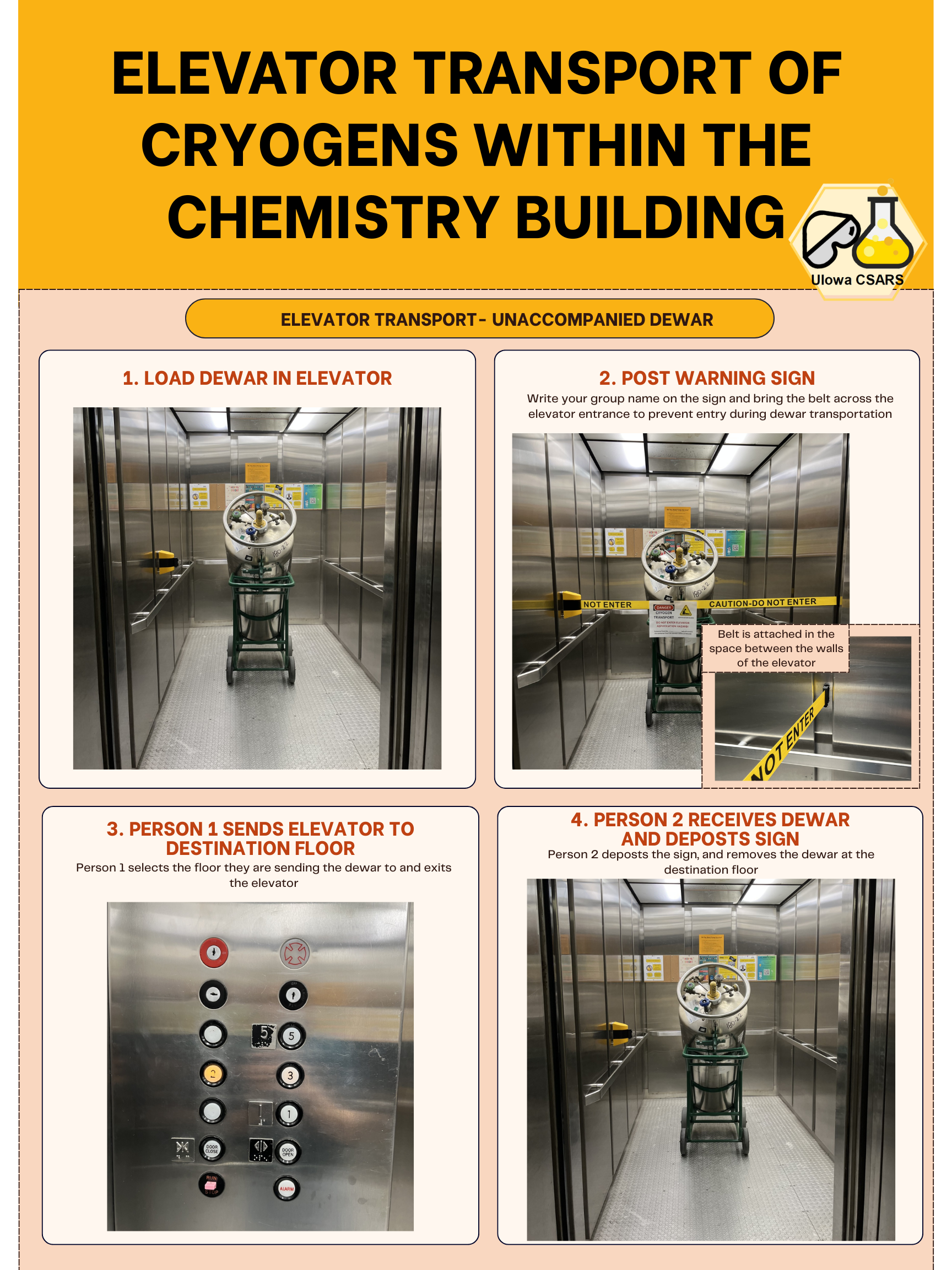

To transport an unaccompanied dewar on the elevator, a sign warning other people to not enter the elevator must be clearly posted. Ideally, transporting unaccompanied cryogen dewars on an elevator should involve two people. The first person will post the warning sign and send the elevator to its destination floor. The second person will receive the cryogen dewar at its destination floor and de-post the warning sign.

If a spill of cryogenic materials in the elevator does occur, press the button to stop at the nearest floor. Block the elevator door open so that it cannot move to the next floor. Notify your supervisor and contact EHS at 319-335-8501 and ask for Rick Byrum (primary contact) or Justin Newnum (secondary contact) for spill response guidance or 911 in case of emergency. For large volume spills, alert others in the area to evacuate.

To Save a Copy of This SOP: Click Here!